Home /

Expert Answers /

Statistics and Probability /

1-what-recommendations-should-ron-garcia-make-with-what-justification-provide-a-detailed-analysis-pa360

(Solved): 1. What Recommendations should Ron Garcia make, with what justification? Provide a detailed analysis ...

1. What Recommendations should Ron Garcia make, with what justification? Provide a detailed analysis with charts,graphs and computer printouts included in order toshow your work

2. Discuss the need for temporary workers in the drawing department.

3. Discuss the plant layout

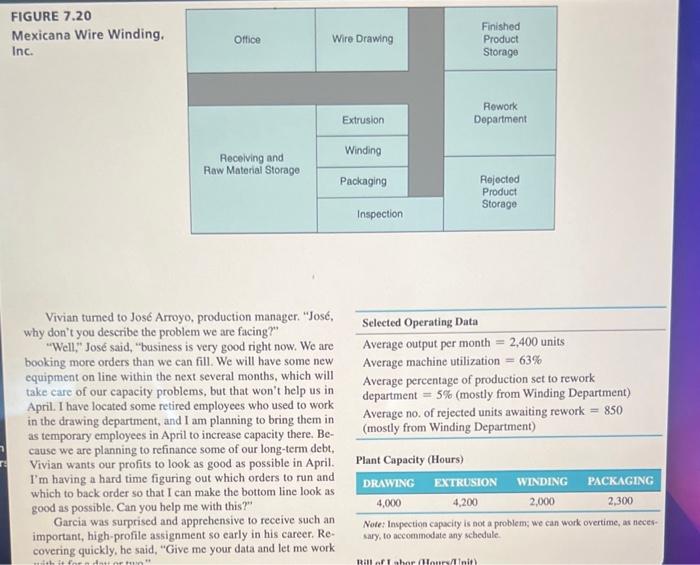

Mexicana Wire Works Ron Garcia felt good about his first week as a management packaging. After inspection, good product is packaged and sent trainee at Mexicana Wire Winding, Inc. He had not yet devel- to finished product storage; defective product is stored sepaoped any technical knowledge about the manufacturing pro- rately until it can be reworked. cess, but he had toured the entire facility, located in the suburbs On March 8, Vivian Espania, Mexicana's general manager, of Mexico City, and had met many people in various areas of stopped by Garcia's office and asked him to attend a staff meetthe operation. ing at 1:00 . Mexicana, a subsidiary of Westover Wire Works, a Texas "Let's get started with the business at hand," Vivian said, firm, is a medium-sized producer of wire windings used in mak- opening the meeting. "You all have met Ron Garcia, our new ing electrical transformers. José Arroyo, the production control management trainee. Ron studied operations management in his manager, described the windings to Garcia as being of stan- MBA program in southern California, so I think he is competent dardized design. Garcia's tour of the plant, laid out by process to help us with a problem we have been discussing for a long type (see Figure 7.20), followed the manufacturing sequence time without resolution. I'm sure that each of you on my staff for the windings: drawing, extrusion, winding, inspection, and will give Ron your full cooperation."

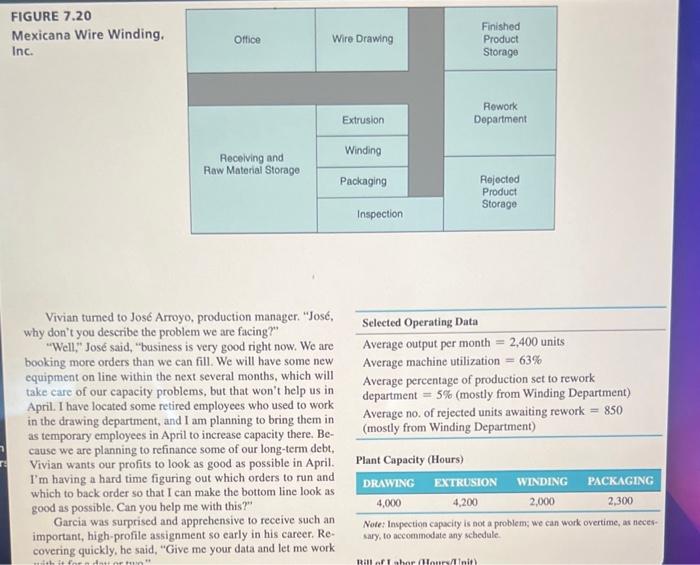

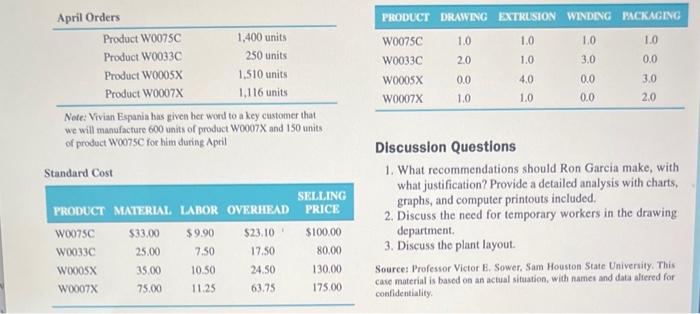

FIGURE Mexicana Wire Winding. Inc. Vivian tumed to José Arroyo, production manager. "José, why don't you describe the problem we are facing " "Well," José said, "business is very good right now. We are Average output per month units booking more orders than we can fill. We will have some new Average machine utilization equipment on line within the next several months, which will Average percentage of production set to rework take care of our capacity problems, but that won't help us in department (mostly from Winding Department) April. I have located some retired employees who used to work in the drawing department, and am planning to bring them in Average no. of rejected units awaiting rework as temporary employees in April to inerease capacity there. Be(mostly from Winding Department) cause we are planning to refinance some of our long-term debt, Vivian wants our profits to look as good as possible in April. Plant Capacity (Hours) I'm having a hard time figuring out which orders to run and which to back order so that I can make the bottom line look as good as possible. Can you help me with this?" Garcia was surprised and apprehensive to receive such an important, high-profile assignment so early in his career. Re- Note: Inspection capucity is not a problem; we can work overtime, as necercovering quickly, he said, "Give me your data and let me work

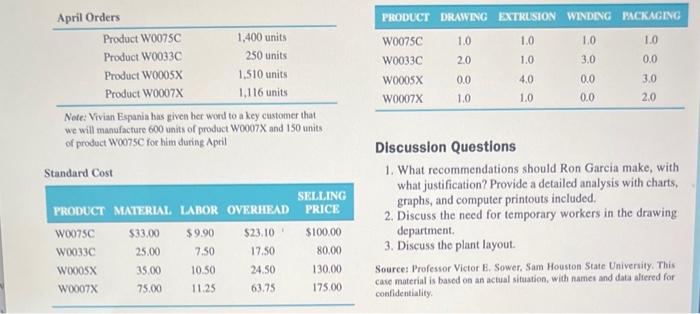

Note: Vivian Espania has given her word to a key customer that we will manufacture 600 units of product W0007 and 150 units. of product Woo7 5C for him during April Discussion Questions Standard Cost 1. What recommendations should Ron Garcia make, with what justification? Provide a detailed analysis with charts. graphs, and computer printouts included. 2. Discuss the need for temporary workers in the drawing department. 3. Discuss the plant layout. Source: Professor Victor B. Sower, Sam Houston State Univernity. This cave material is based on an actual situation, with namet and data altered for confidentiality.

Expert Answer

AnswersObjective function: Maximum profitTo make the optimum profit by satisying the limitations total units ofHERE IS THE SOME POINTS FOR ABOVE QUEST