Home /

Expert Answers /

Operations Management /

3-a-t-shirt-manufacturer-started-a-new-production-plant-the-plant-manager-wishes-to-optimize-the-pa516

(Solved): 3. A T-shirt manufacturer started a new production plant. The plant manager wishes to optimize the ...

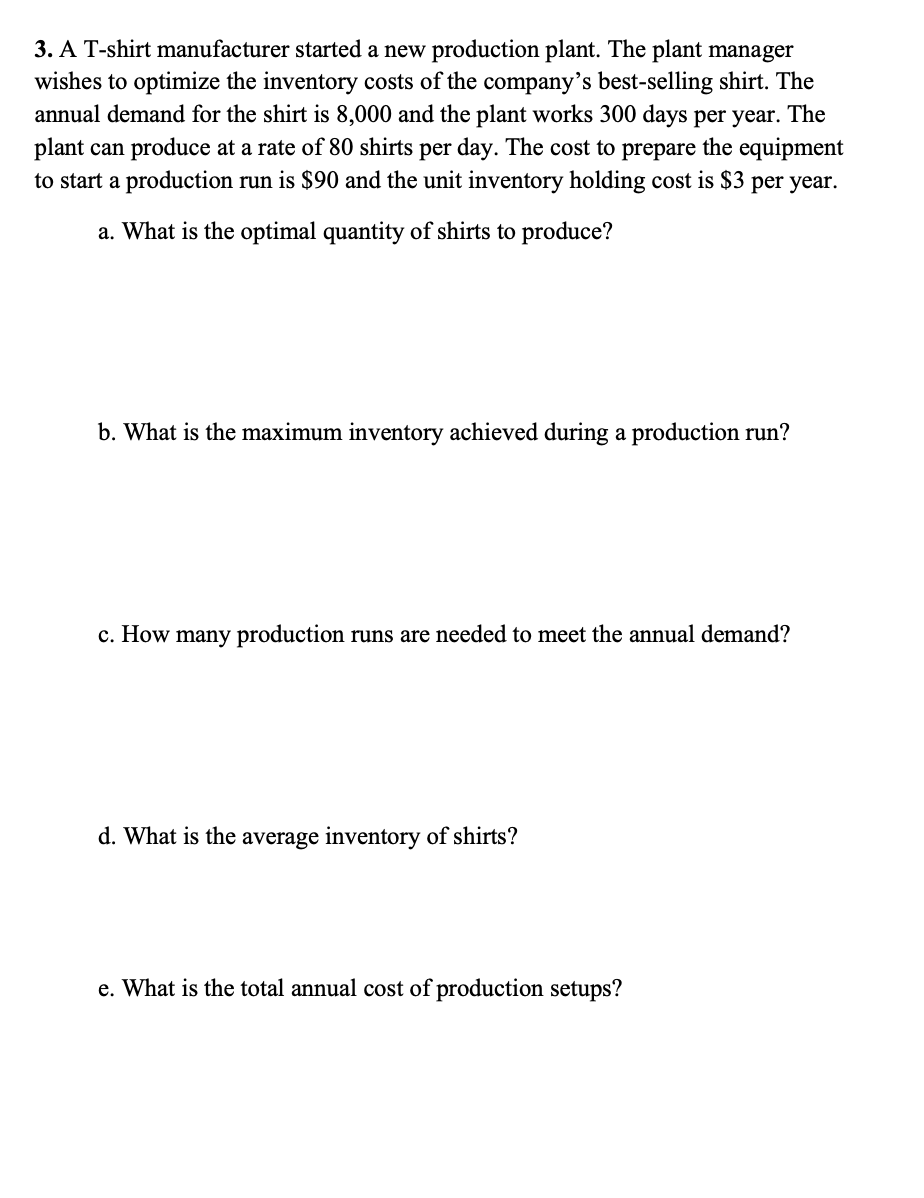

3. A T-shirt manufacturer started a new production plant. The plant manager wishes to optimize the inventory costs of the company's best-selling shirt. The annual demand for the shirt is 8,000 and the plant works 300 days per year. The plant can produce at a rate of 80 shirts per day. The cost to prepare the equipment to start a production run is $90 and the unit inventory holding cost is $3 per year. a. What is the optimal quantity of shirts to produce? b. What is the maximum inventory achieved during a production run? c. How many production runs are needed to meet the annual demand? d. What is the average inventory of shirts? e. What is the total annual cost of production setups?

Expert Answer

Monthly demand = 3,000 A = annual demand = 12 x 3000 = 36,000 shirts Company operates for 240 days in a year d = daily demand = 36,000/240 = 150 shirts per day S = cost per setup = $200 H = Annual holding c