Home /

Expert Answers /

Mechanical Engineering /

3-your-boss-sends-you-out-to-review-productivity-at-an-automated-upsetting-forge-the-operation-c-pa764

(Solved): 3. Your boss sends you out to review productivity at an automated upsetting forge. The operation c ...

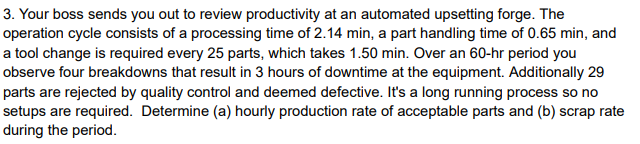

3. Your boss sends you out to review productivity at an automated upsetting forge. The operation cycle consists of a processing time of , a part handling time of , and a tool change is required every 25 parts, which takes . Over an 60 -hr period you observe four breakdowns that result in 3 hours of downtime at the equipment. Additionally 29 parts are rejected by quality control and deemed defective. It's a long running process so no setups are required. Determine (a) hourly production rate of acceptable parts and (b) scrap rate during the period.

Expert Answer

a) The total processing time per part is 2.14min+0.65min=2.79min. The tool change time is 1.50 min and it is req