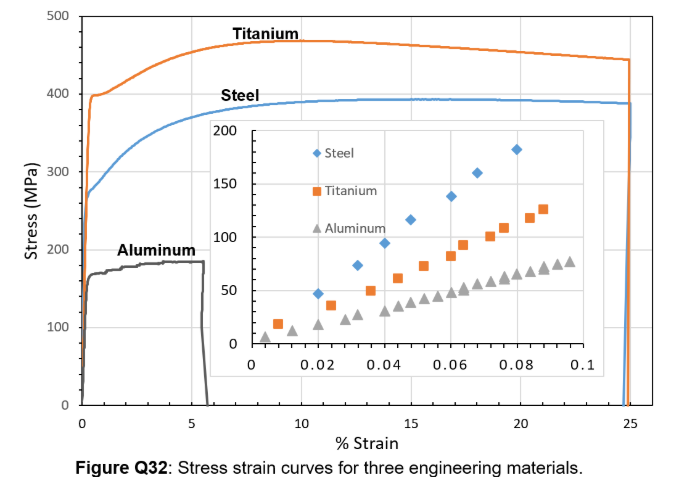

(Solved): (i) Which of these materials (in Figure Q32) exhibit high toughness? Explain your answer. (ii) Estim ...

(i) Which of these materials (in Figure Q32) exhibit high toughness? Explain your answer. (ii) Estimate the yield strengths for each material and explain how you obtain your values. (iii) Determine engineering and true stress for titanium and steel at fracture. Explain why the engineering and true stress values are different for the same material. (iv) Taking the yield strain of steel to be 0.08%, determine the Modulus of Resilience (MoR) for steel. What engineering function does MoR enable? (v) From the linear portion (inset in Fig Q32) of the stress–strain curves, determine Young’s Modulus (E) for each engineering material. (vi) Given that the densities of Steel, Titanium and Aluminum are respectively, 7800, 4,500 and 2,700 kg/m3, compare their specific moduli and hence rank each of these for use as a structural component in a transport machine. Give reasons for your ranking. (vii) If the steel is to be used to manufacture a rotating shaft, determine the modulus of rigidity. What function does the modulus of rigidity enable in a rotating shaft? Figure Q32: Stress strain curves for three engineering materials.