Home /

Expert Answers /

Mechanical Engineering /

in-the-double-reduction-spur-gear-train-shown-in-the-figure-the-shaft-is-driven-by-a-motor-attached-pa518

(Solved): in the double reduction spur gear train shown in the figure, the shaft is driven by a motor attached ...

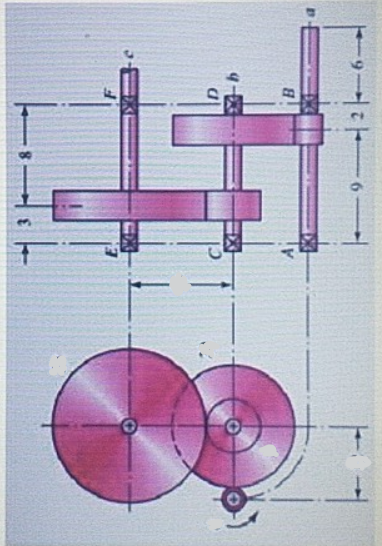

in the double reduction spur gear train shown in the figure, the shaft is driven by a motor attached by a flexible coupling connected to the output. the motor provides a torque of 2500 lbf.in a speed of 1800 RPM. the gears have a pressure angle of 20° and a pitch of 8 teeth per inch. the output C shaft is desired to provide 900 RPM with up to 2% variation determines the fatigue wear safety factor for the output. consider that the pinions are fabricated in brushed brass while the gears are fabricated in carbon steel (AIS 1020 CD) with hobbing. it is up to the designer to determine the face width but F>1in note: must respect the design standards.

D