(Solved): One method that is used to grow nanowires (nanotubes with solid cores) is to initially deposit a sma ...

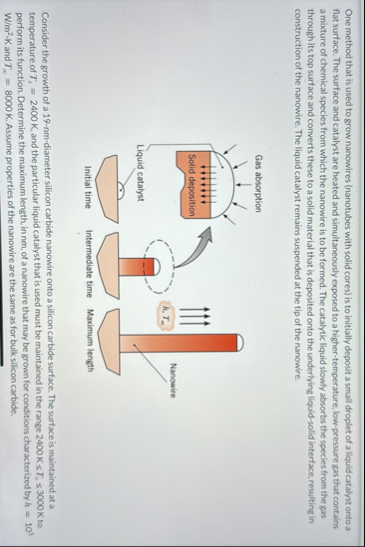

One method that is used to grow nanowires (nanotubes with solid cores) is to initially deposit a small droplet of a liquid catalyst onto a flat surface. The surface and catalyst are heated and simultaneously exposed to a higher-temperature, low-pressure gas that contains a mixture of chemical species from which the nanowire is to be formed. The catalytic liquid slowly absorbs the species from the gas through its top surface and converts these to a solid material that is deposited onto the undertying tlquid-sollid inferface, resulting in construction of the nanowire. The liquid catalyst remains suspended at the tip of the nanowire. Consider the growth of a 19 -nm-diameter silicon carbide nanowire onto a silicon carbide surface. The surface is maintained at a temperature of

T_(s)=2400K, and the particular liquid catalyst that is used must be maintained in the range

2400K<=T_(c)<=3000Kto perform its function. Determine the maximum length, in nm, of a nanowire that may be grown for conditions characterized by

h=10^(5)

(W)/(m^(2))*Kand

T_(\infty )=8000K. Assume properties of the nanowire are the same as for bulk silicon carbide.