Home /

Expert Answers /

Operations Management /

please-asapp-i-have-only-30-minutes-please-help-me-answer-in-your-own-terms-asappp-please-follow-th-pa745

(Solved): Please ASAPP I HAVE ONLY 30 MINUTES PLEASE HELP ME. answer in your own terms ASAPPP PLEASE FOLLOW TH ...

Please ASAPP I HAVE ONLY 30 MINUTES PLEASE HELP ME. answer in your own terms ASAPPP PLEASE FOLLOW THE INSTRUCTIONS

SUBJECT: Strategic Management

Case Study SWOT Analysis of: Automation at Boeing

???????

The following are the general guidelines for this assignment:

Minimum 650 words for this case

Recommendations are also to be provided with the SWOT as a 5th section.

No SWOT will contain more than 3 items for any part of the assignment (S,W,O,T or Recommendations). This is to reinforce the importance of the SWOT model as a tool used for depth in analysis—not breadth.

All analysis is to be from the perspective of the company—not the individual employee.

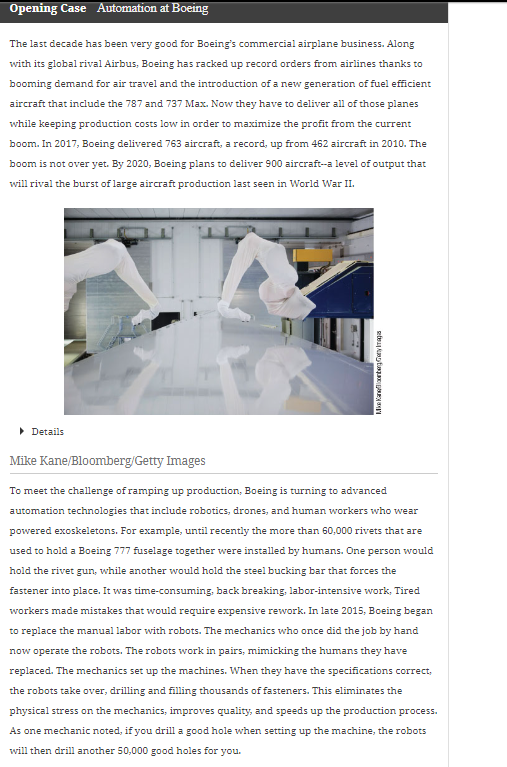

The last decade has been very good for Boeing's commercial airplane business. Along with its global rival Airbus, Boeing has racked up record orders from airlines thanks to booming demand for air travel and the introduction of a new generation of fuel efficient aircraft that include the 787 and . Now they have to deliver all of those planes while keeping production costs low in order to maximize the profit from the current boom. In 2017, Boeing delivered 763 aircraft, a record, up from 462 aircraft in 2010. The boom is not over yet. By 2020 , Boeing plans to deliver 900 aircraft-a level of output that will rival the burst of large aircraft production last seen in World War II. Details Mike Kane/Bloomberg/Getty Images To meet the challenge of ramping up production, Boeing is turning to advanced automation technologies that include robotics, drones, and human workers who wear powered exoskeletons. For example, until recently the more than 60,000 rivets that are used to hold a Boeing 777 fuselage together were installed by humans. One person would hold the rivet gun, while another would hold the steel bucking bar that forces the fastener into place. It was time-consuming, back breaking, labor-intensive work, Tired workers made mistakes that would require expensive rework, In late 2015, Boeing began to replace the manual labor with robots. The mechanics who once did the job by hand now operate the robots. The robots work in pairs, mimicking the humans they have replaced. The mechanics set up the machines. When they have the specifications correct, the robots take over, drilling and filling thousands of fasteners. This eliminates the physical stress on the mechanics, improves quality, and speeds up the production process. As one mechanic noted, if you drill a good hole when setting up the machine, the robots will then drill another 50,000 good holes for you.

Similar systems can be found on the Boeing 737 production line. A new robotic system drills holes in the main beams inside each wing, known as spars, again replacing human. labor. This speeds up the process, requires half the space that was used in the prior production process, cuts the amount of rework required by production glitches, reduces injuries to human labor, and is supporting a sharp increase in output at Boeing's Renton factory near Seattle where the 737 is produced. In 2005 , it took 9,300 workers at the Renton factory to build 21 planes per month. By 2018, some 12,000 employees, an increase of , were producing double the output, or 52 planes per month. This represents a dramatic increase in both labor productivity and the productivity of the capital invested in the factory, which translates into lower costs for Boeing, enabling it to make more profit from every plane that rolls off the end of the line. In the factory producing carbon fiber wings for the new , Boeing has taken automation even further. The composite wings are built up by a robot that operates like a giant tape dispenser, zipping back and forth along a 110 -foot mold laying carbon fiber strips, building up the wing layer by layer. As the robot traverses the wing at various angles, it lays down piles of epoxy-resin-infused carbon fiber in about 300 separately programmed runs. The process takes place in a "clean room" and is overseen by two employees dressed in lab coats. The completed wing is then moved into an oven, where it is baked for seven hours while a single employee oversees the process. As the use of robotic systems and carbon fiber proliferates, employment levels at Boeing are unlikely to increase much, even as production expands rapidly. While Boeing employed 100,000 at its factories in Washington State in the late 1990s, today its workforce is down to 66,000 even though output has increased sharply. Sources: Guy Norris, "Eosing to push 900 deliveries per year," Aviation Daily, January . Dominie Gates, "Bosing retools Renton plant with automation for big 737 ramp up," Seattle Time 5, April 18, 2015. Dominic Gates, "Bosing revs up robots for 777x," Seattle Iimes, Oetober 23, 201 7.

Expert Answer

SWOT Analysis of Automation at BoeingStrengths:Increased Efficiency: By replacing human labor with automation technologies such as robots and drones,