(Solved): Q5 [5 Marks] Part a: A chemical plant tracks the following safety performance over five years: Total ...

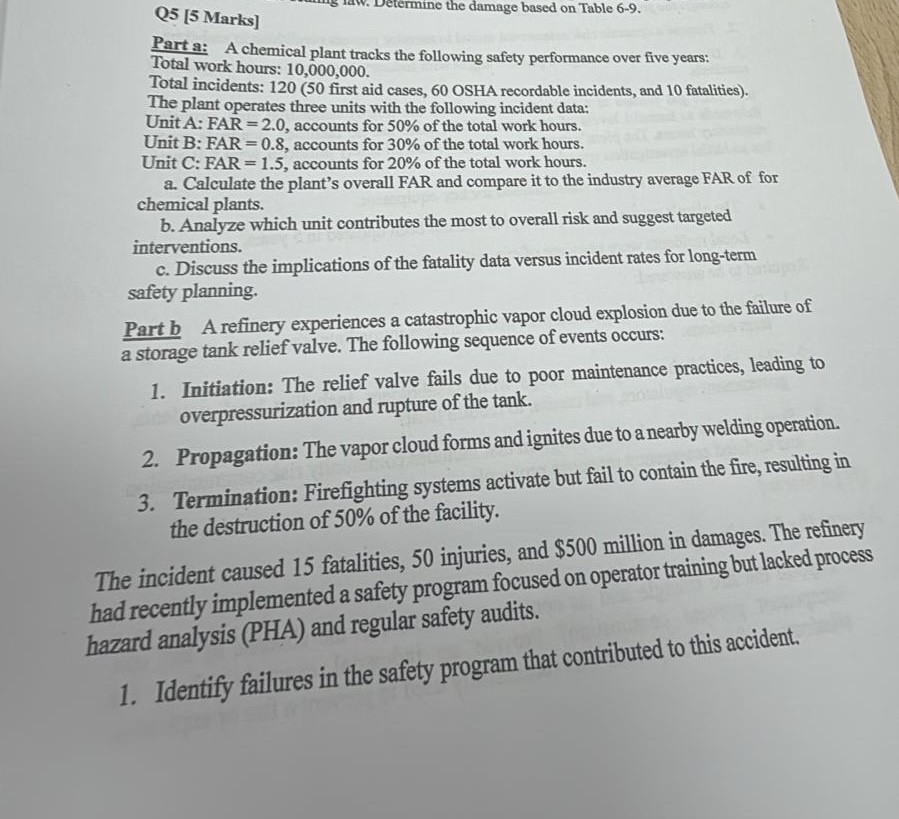

Q5 [5 Marks] Part a: A chemical plant tracks the following safety performance over five years: Total work hours:

10,000,000. Total incidents: 120 ( 50 first aid cases, 60 OSHA recordable incidents, and 10 fatalities). The plant operates three units with the following incident data: Unit A: FAR

=2.0, accounts for

50%of the total work hours. Unit B: FAR

=0.8, accounts for

30%of the total work hours. Unit C:

FAR=1.5, accounts for

20%of the total work hours. a. Calculate the plant's overall FAR and compare it to the industry average FAR of for chemical plants. b. Analyze which unit contributes the most to overall risk and suggest targeted interventions. c. Discuss the implications of the fatality data versus incident rates for long-term safety planning. Part b A refinery experiences a catastrophic vapor cloud explosion due to the failure of a storage tank relief valve. The following sequence of events occurs: Initiation: The relief valve fails due to poor maintenance practices, leading to overpressurization and rupture of the tank. Propagation: The vapor cloud forms and ignites due to a nearby welding operation. Termination: Firefighting systems activate but fail to contain the fire, resulting in the destruction of

50%of the facility. The incident caused 15 fatalities, 50 injuries, and

$500million in damages. The refinery had recently implemented a safety program focused on operator training but lacked process hazard analysis (PHA) and regular safety audits. Identify failures in the safety program that contributed to this accident.