Home /

Expert Answers /

Mechanical Engineering /

selected-list-of-instruments-in-mechanical-engineering-6-feeler-gauge-7-thermister-8-barometer-9-pa206

(Solved): Selected list of Instruments in Mechanical Engineering 6. Feeler Gauge 7. Thermister 8. Barometer 9 ...

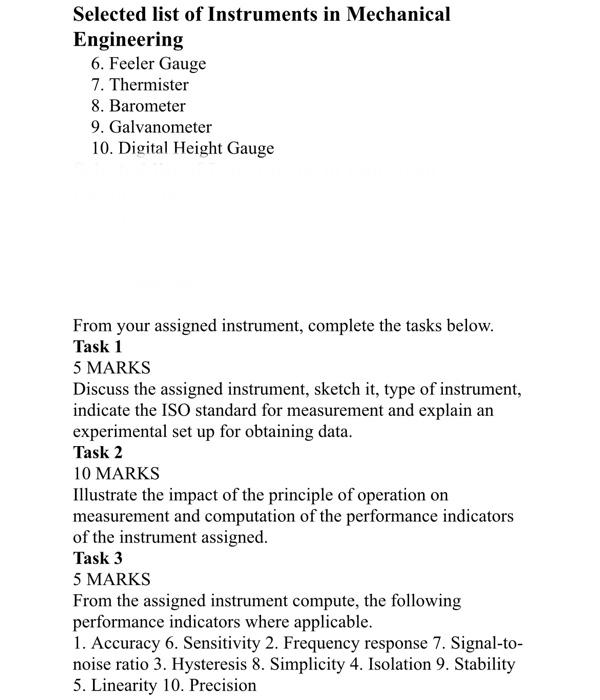

Selected list of Instruments in Mechanical Engineering 6. Feeler Gauge 7. Thermister 8. Barometer 9. Galvanometer 10. Digital Height Gauge From your assigned instrument, complete the tasks below. Task 1 5 MARKS Discuss the assigned instrument, sketch it, type of instrument, indicate the ISO standard for measurement and explain an experimental set up for obtaining data. Task 2 10 MARKS Illustrate the impact of the principle of operation on measurement and computation of the performance indicators of the instrument assigned. Task 3 5 MARKS From the assigned instrument compute, the following performance indicators where applicable. 1. Accuracy 6 . Sensitivity 2 . Frequency response 7. Signal-tonoise ratio 3. Hysteresis 8 . Simplicity 4. Isolation 9 . Stability 5. Linearity 10 . Precision

Expert Answer

A feeler gauge is a mechanical tool used to measure the gap or clearance between two objects. It consists of a set of thin, flat metal strips of various thicknesses. These strips, known as blades, are individually marked with their thickness measurement. Feeler gauges are commonly used in mechanical engineering for tasks such as measuring valve clearances, spark plug gaps, and other small gaps or clearances in machinery.Type of Instrument: The feeler gauge falls under the category of a mechanical measuring instrument.ISO Standard: The ISO standard for measurement related to feeler gauges is ISO 10109:2013 - Geometrical product specifications (GPS) -- Cylindrical gauges for internal dimensions.Experimental Setup for Obtaining Data: To obtain data using a feeler gauge, follow these steps:Identify the two objects between which the gap or clearance needs to be measured.Select an appropriate blade from the feeler gauge set that fits into the gap without any force.Insert the blade into the gap and check for a snug fit. The blade should slide in without being too loose or too tight.Once you find the blade that fits perfectly, note down the marked thickness of the blade.Repeat the process for different gaps or clearances, using different blades from the feeler gauge set.Task 2: Illustrating the impact of the principle of operation on measurement and computation of performance indicators.Principle of Operation: The principle of operation for a feeler gauge is based on the mechanical interference between the blade and the objects being measured. The blade is inserted into the gap, and its thickness is determined by the smallest blade that fits without any force. The principle relies on the physical property of the blade to accurately measure the gap or clearance.Impact on Measurement and Performance Indicators:Accuracy: The accuracy of a feeler gauge depends on the precision of the blade thicknesses and the user's ability to identify the correct fit. It is crucial to select the appropriate blade that accurately represents the measured gap.Sensitivity: Feeler gauges can have different levels of sensitivity based on the range of thicknesses available in the set. A gauge with finer gradations between blade thicknesses offers higher sensitivity.Hysteresis: Hysteresis is not applicable to feeler gauges as it is a phenomenon associated with the lagging or delayed response of a system.Linearity: Feeler gauges are considered linear since the blade thickness markings provide a linear scale for measuring the gap.Precision: The precision of the measurement depends on the quality of the blade manufacturing and the user's skill in selecting the appropriate blade for each measurement.Simplicity: Feeler gauges are relatively simple to use and understand, requiring minimal training and setup.Stability: Stability is not a significant concern for feeler gauges, as they are not sensitive to environmental factors.Isolation: Isolation is not applicable to feeler gauges, as they do not involve the separation of variables or protection against external influences.Frequency Response: Frequency response is not applicable to feeler gauges, as they are not designed to measure dynamic or time-varying quantities.Signal-to-Noise Ratio: Signal-to-noise ratio is not applicable to feeler gauges since they do not involve the amplification or filtering of signals.Task 3: Computing the performance indicators for the assigned instrument.From the assigned instrument (Feeler Gauge), the applicable performance indicators are:Accuracy: Accuracy is the ability of the feeler gauge to provide measurements close to the true value. It depends on the precision of the blade thicknesses and the user's skill in selecting the correct blade. Accuracy can be evaluated by comparing the measured gaps with known reference values.Sensitivity: Sensitivity refers to the smallest change in gap or clearance that can be detected by the feeler gauge. It depends on the range and gradations of thicknesses available in the feeler gauge set. A gauge with finer gradations between blade thicknesses offers higher sensitivity.Frequency Response: Frequency response is not applicable to feeler gauges, as they are primarily used for static measurements and do not measure dynamic or time-varying quantities.Signal-to-Noise Ratio: Signal-to-noise ratio is not applicable to feeler gauges since they do not involve the amplification or filtering of signals.Hysteresis: Hysteresis is not applicable to feeler gauges, as it is a phenomenon associated with the lagging or delayed response of a system.Simplicity: Feeler gauges are considered simple instruments as they have a straightforward design and are easy to use, requiring minimal training and setup.Isolation: Isolation is not applicable to feeler gauges, as they do not involve the separation of variables or protection against external influences.Stability: Stability is not a significant concern for feeler gauges, as they are not sensitive to environmental factors and do not have components that may drift over time.Linearity: Feeler gauges are considered linear instruments since the blade thickness markings provide a linear scale for measuring the gap.Precision: Precision refers to the repeatability and consistency of measurements. The precision of a feeler gauge depends on the quality of blade manufacturing and the user's skill in selecting the appropriate blade for each measurement. Higher precision can be achieved by using feeler gauges with blades of smaller thickness increments.Please note that the computation of numerical values for performance indicators would require specific data and specifications for the feeler gauge being used.