(Solved): Use the general shaft layout given and determine critical diameters of the shaft based on infinite f ...

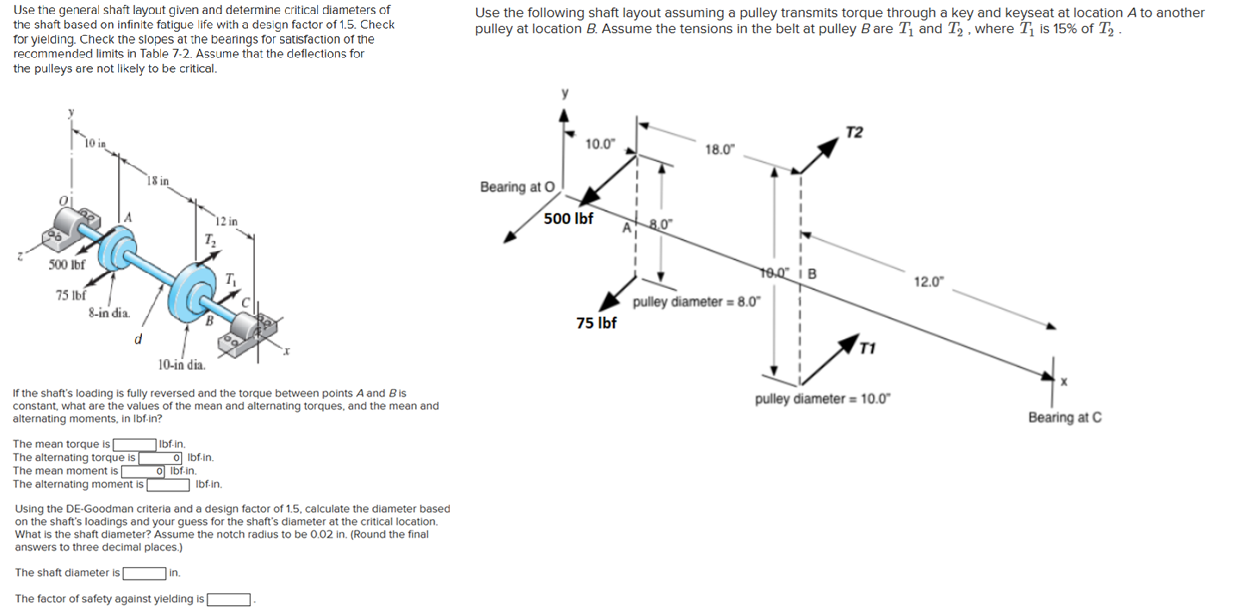

Use the general shaft layout given and determine critical diameters of the shaft based on infinite fatigue life with a design factor of 1.5. Check for yielding. Check the slopes at the bearings for satisfaction of the recommended limits in Table 7.2. Assume that the deflections for the pulleys are not likely to be critical. If the shaft's loading is fully reversed and the torque between points \( A \) and \( B \) is constant, what are the values of the mean and alternating torques, and the mean and alternating moments, in lbfin? The mean torque is The alternating torque ic \( \frac{0}{0} \mathrm{Ibf} \).in. The mean moment is bf-in. The alternating moment is Ibf.in. Using the DE-Goodman criteria and a design factor of 1.5, calculate the diameter based on the shaft's loadings and your guess for the shaft's diameter at the critical location. What is the shaft diameter? Assume the notch radius to be 0.02 in. (Round the final answers to three decimal places.) The shaft diameter is in. Use the following shaft layout assuming a pulley transmits torque through a key and keyseat at location \( A \) to another pulley at location \( B \). Assume the tensions in the belt at pulley \( B \) are \( T_{1} \) and \( T_{2} \), where \( T_{1} \) is \( 15 \% \) of \( T_{2} \).