(Solved): Using the isothermal transformation diagram for a 0.45wt%C steel alloy below, determine the final mi ...

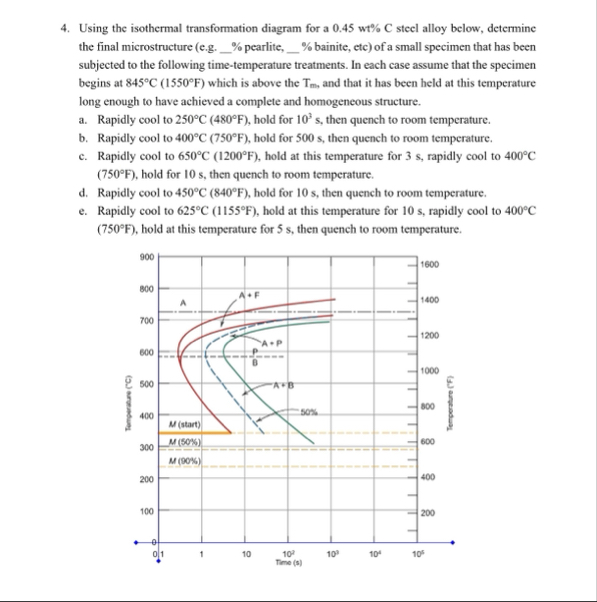

Using the isothermal transformation diagram for a

0.45wt%Csteel alloy below, determine the final microstructure (e.g.

q,% pearlite,

q,% bainite, etc) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen begins at

845\deg C(1550\deg F)which is above the

T_(m), and that it has been held at this temperature long enough to have achieved a complete and homogeneous structure. a. Rapidly cool to

250\deg C(480\deg F), hold for

10^(3)s, then quench to room temperature. b. Rapidly cool to

400\deg C(750\deg F), hold for 500 s , then quench to room temperature. c. Rapidly cool to

650\deg C(1200\deg F), hold at this temperature for 3 s , rapidly cool to

400\deg C

(750\deg F), hold for 10 s , then quench to room temperature. d. Rapidly cool to

450\deg C(840\deg F), hold for 10 s , then quench to room temperature. e. Rapidly cool to

625\deg C(1155\deg F), hold at this temperature for 10 s , rapidly cool to

400\deg C

(750\deg F), hold at this temperature for 5 s , then quench to room temperature.