Home /

Expert Answers /

Operations Management /

xyz-industries-manufactures-automotive-parts-with-the-following-data-annual-demand-d-36-000-units-pa809

(Solved): XYZ Industries manufactures automotive parts with the following data: Annual demand (D)=36,000 units ...

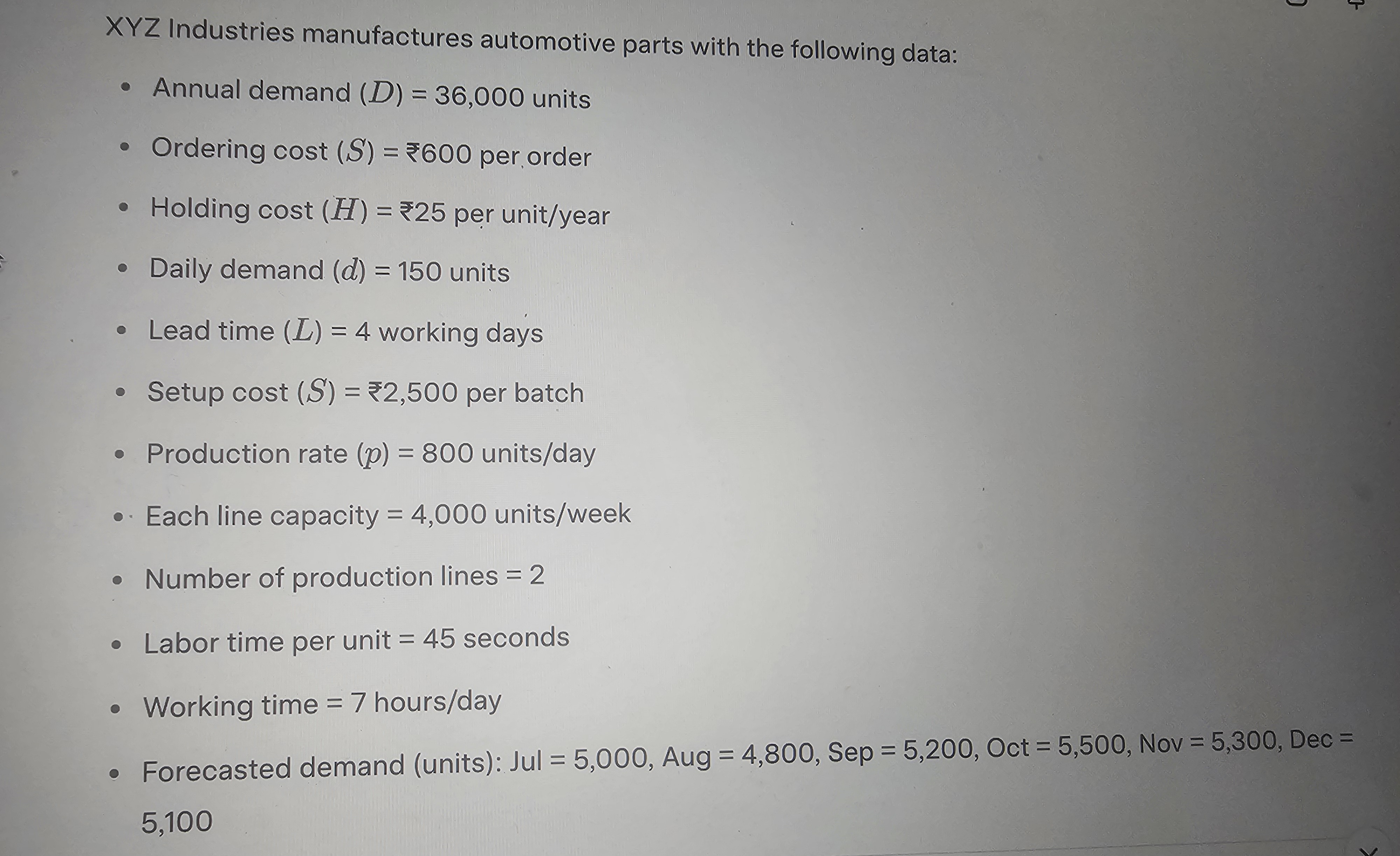

XYZ Industries manufactures automotive parts with the following data:

Annual demand (D)=36,000 units

5Ordering cost (S)=₹600 per order

Holding cost (H)=₹25 per uni(t)/(y)ear

Daily demand (d)=150 units

Lead time (L)=4 working days

Setup cost (S)=₹2,500 per batch

Production rate (p)=800 unit(s)/(d)ay

Each line capacity =4,000 unit(s)/(w)eek

Number of production lines =2

Labor time per unit =45 seconds

Working time =7 hour(s)/(d)ay

Forecasted demand (units): Jul=5,000,Aug=4,800,Sep=5,200,Oct=5,500,Nov=5,300,Dec=

5,100 1.1. Calculate the Economic Order Quantity (EOQ).

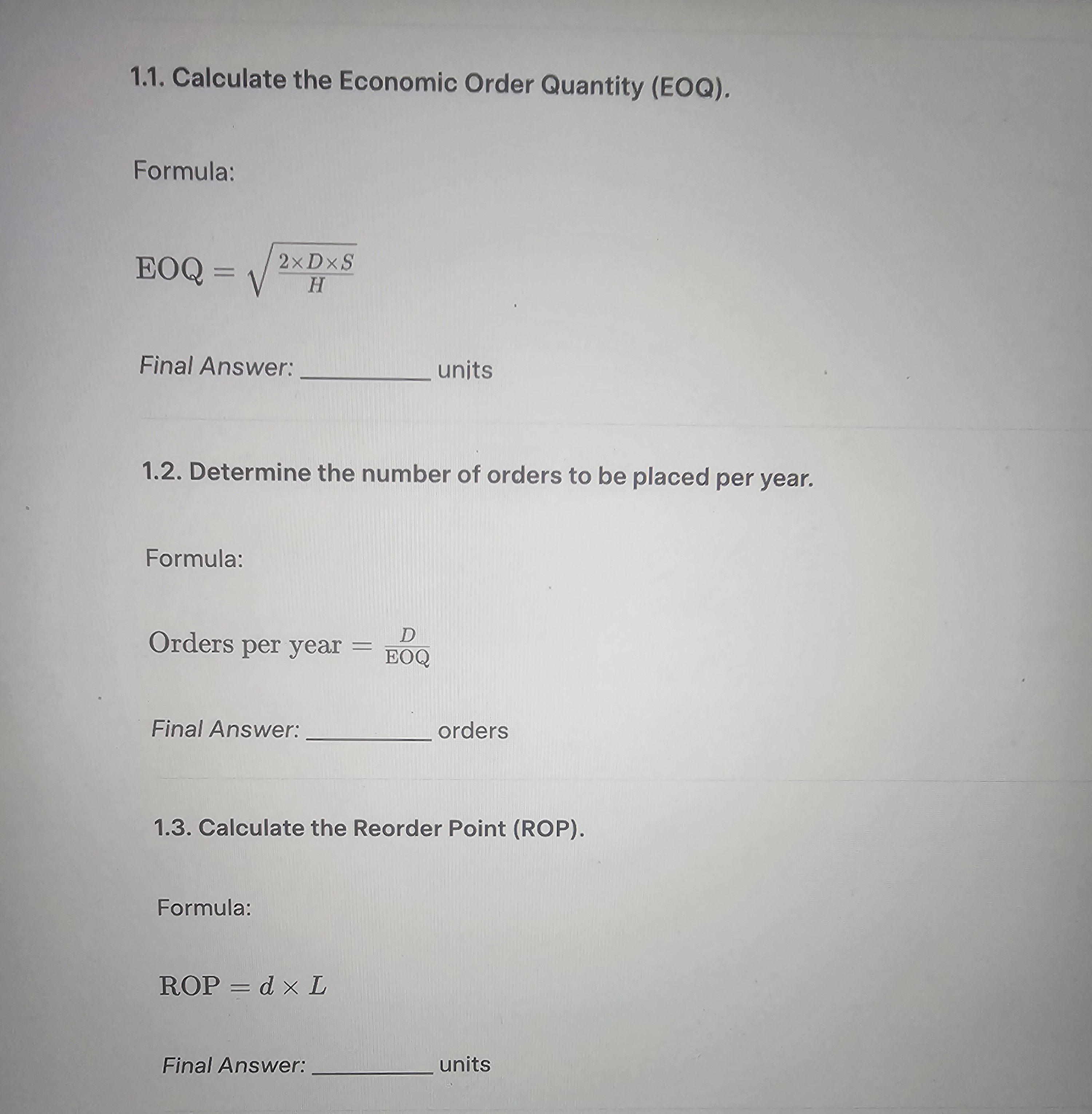

Formula:

EOQ=\sqrt((2\times D\times S)/(H))

Final Answer:

units

1.2. Determine the number of orders to be placed per year.

Formula:

Orders per year =(D)/(EOQ)

Final Answer:

orders

1.3. Calculate the Reorder Point (ROP).

Formula:

ROP=d\times L

Final Answer:

units 1.4. Calculate the Economic Production Quantity (EPQ).

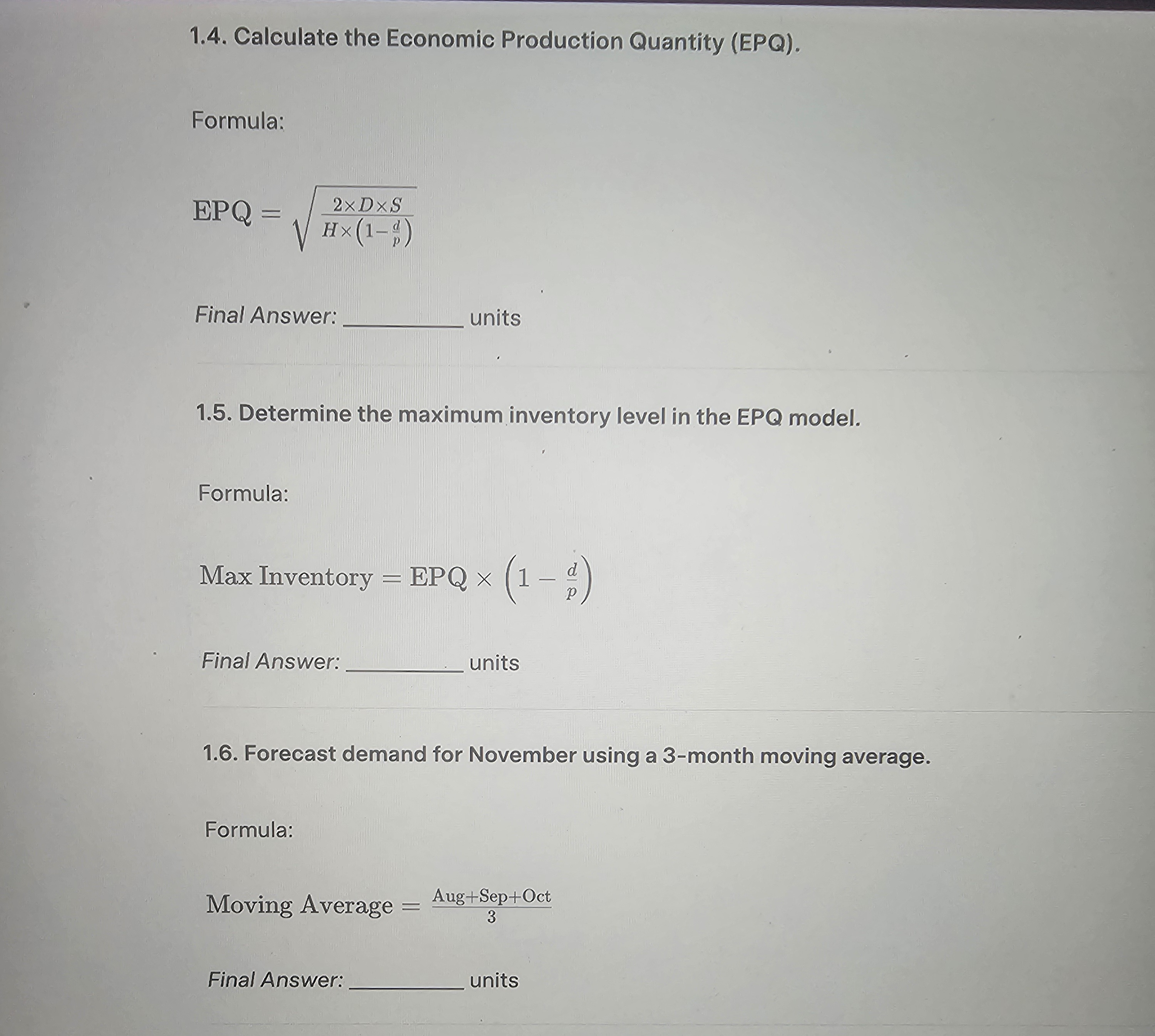

Formula:

EPQ=\sqrt((2\times D\times S)/(H\times (1-(d)/(p))))

Final Answer:

units

1.5. Determine the maximum inventory level in the EPQ model.

Formula:

Max Inventory =EPQ\times (1-(d)/(p))

Final Answer:

units

1.6. Forecast demand for November using a 3-month moving average.

Formula:

Moving Average =( Aug + Sep + Oct )/(3)

Final Answer:

units 1.7. Determine the minimum number of workstations required.

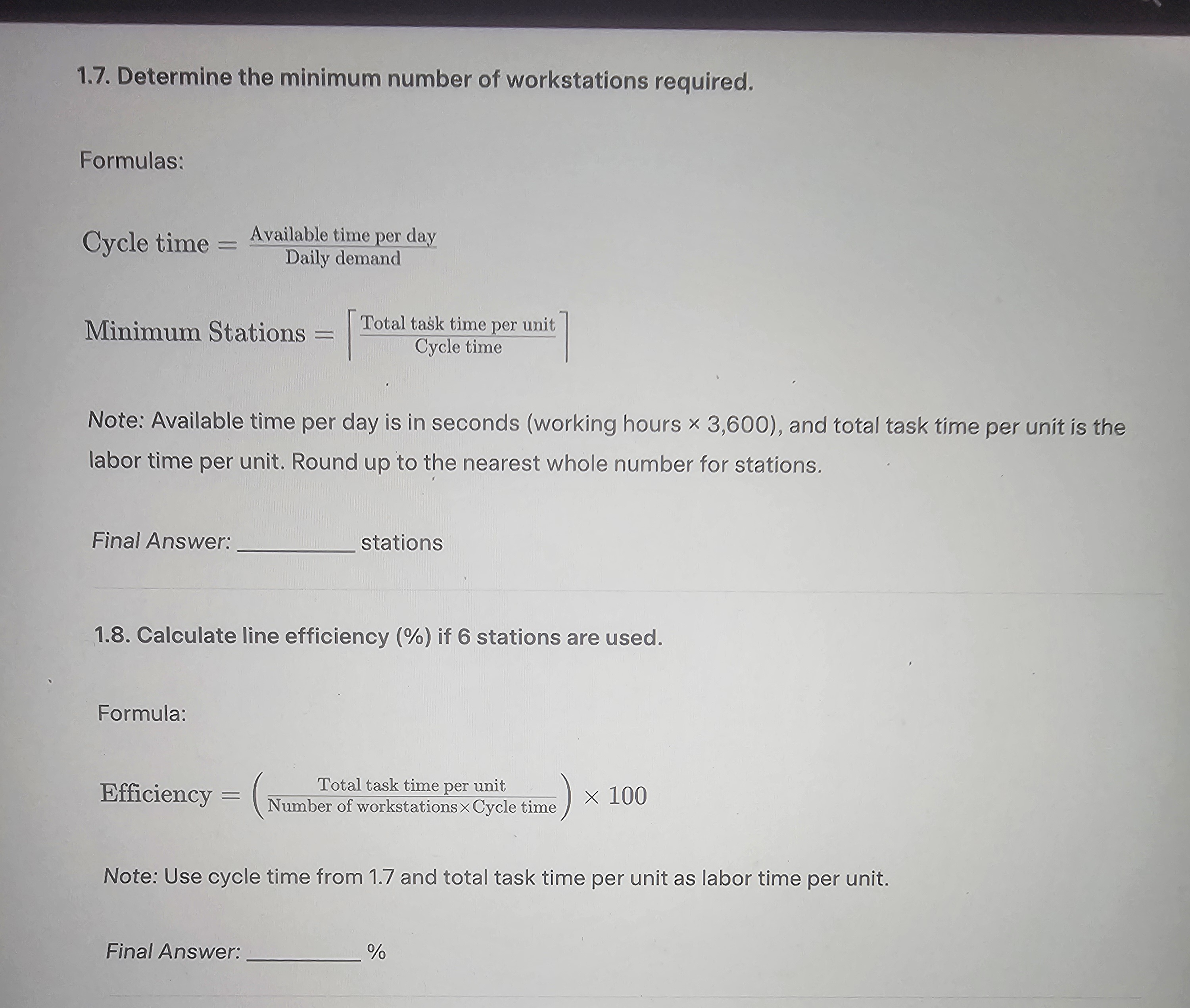

Formulas:

Cycle time =( Available time per day )/( Daily demand )

Minimum Stations =|~( Total task time per unit )/( Cycle time )~|\times 3,600 =(( Total task time per unit )/( Number of workstations \times Cycle time ))\times 100

Note: Use cycle time from 1.7 and total task time per unit as labor time per unit.

Final Answer:

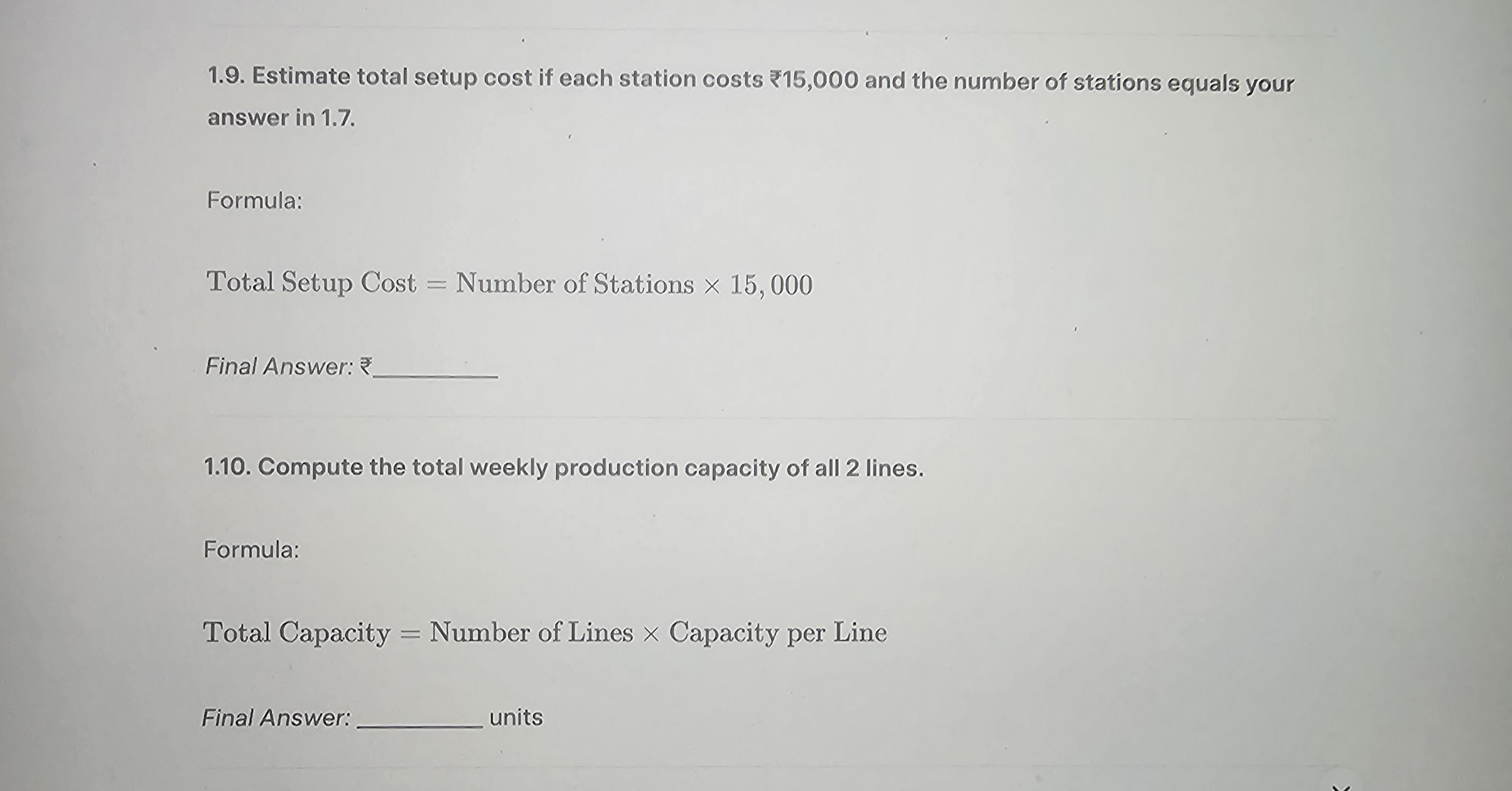

%1.9. Estimate total setup cost if each station costs ₹15,000 and the number of stations equals your

answer in 1.7.

Formula:

Total Setup Cost = Number of Stations \times 15,000

Final Answer: ₹

1.10. Compute the total weekly production capacity of all 2 lines.

Formula:

Total Capacity = Number of Lines \times Capacity per Line

Final Answer:

units5